Future of PCF Fixtures in Smart Manufacturing

Discover how PCF fixtures will shape the future of smart manufacturing, improving efficiency, precision, and automation in production processes.

The world of manufacturing is rapidly evolving, with new technologies revolutionizing how products are designed, produced, and assembled. One of the key components driving this transformation is the integration of PCF fixtures (Precision Clamping Fixtures) into the smart manufacturing ecosystem. These fixtures are becoming indispensable in improving the efficiency, precision, and safety of manufacturing processes.

As manufacturers look toward the future, the role of PCF fixtures in smart manufacturing is expected to grow. With the rise of automation, artificial intelligence (AI), and the Internet of Things (IoT), PCF fixtures are evolving to meet the demands of modern production lines. Let’s take a closer look at the future of PCF fixtures and how they will shape the manufacturing landscape.

In this article, we’ll explore how PCF fixtures can enhance smart manufacturing, improve operational efficiency, and tackle the challenges of the future.

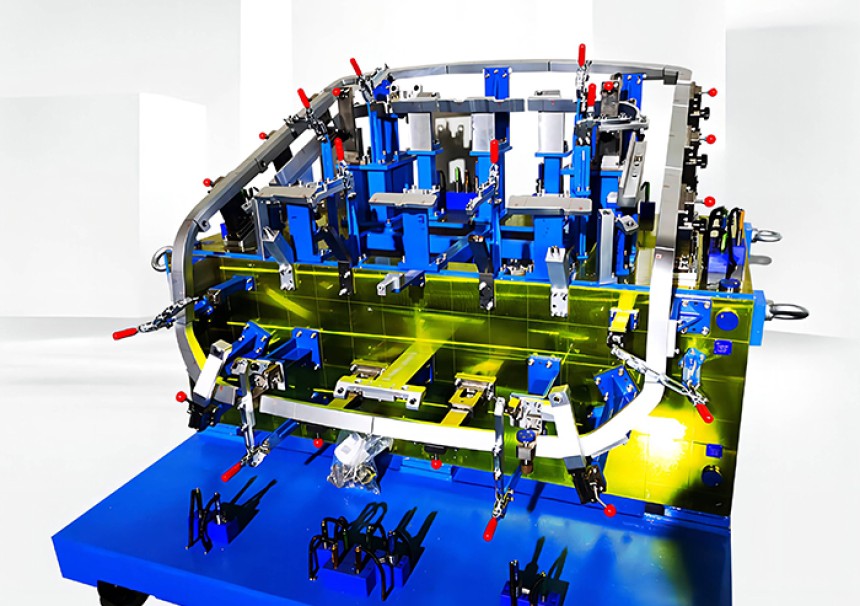

1. What Are PCF Fixtures and Why Are They Important?Before diving into the future of PCF fixtures, let’s quickly define what they are and why they are essential to modern manufacturing. PCF fixtures are specialized devices used to hold parts securely during the manufacturing process, ensuring precision and consistency. These fixtures are used in various industries such as automotive, aerospace, and electronics, where accuracy is critical.

The importance of PCF fixtures lies in their ability to prevent part misalignment, reduce human error, and improve the overall quality of the product. As smart manufacturing continues to push the boundaries of automation and technology, PCF fixtures are evolving to become more adaptable, efficient, and intelligent.

2. The Role of Smart Manufacturing in the FutureSmart manufacturing is all about using advanced technologies like IoT, AI, and robotics to create more intelligent, flexible, and efficient production systems. This type of manufacturing relies heavily on real-time data, automation, and connectivity to streamline operations and improve decision-making.

As the demand for precision and speed in manufacturing increases, PCF fixtures will play a crucial role in smart factories. These fixtures will not only ensure that parts are securely held but also integrate with automated systems to increase throughput and minimize downtime.

3. Automation and PCF Fixtures: A Perfect PairOne of the key drivers of smart manufacturing is automation. Automated systems, such as robotic arms and conveyor belts, are being integrated into production lines to handle repetitive tasks, reduce labor costs, and improve speed.

PCF fixtures will be crucial in supporting these automated systems. With the ability to securely hold parts during automated machining, assembly, and testing, these fixtures will ensure that the production process remains smooth and precise. Automated PCF fixtures will also allow for quicker setups and adjustments, which will reduce downtime and increase overall efficiency.

4. IoT-Enabled PCF Fixtures for Real-Time MonitoringThe integration of the Internet of Things (IoT) into manufacturing processes is one of the most exciting advancements in the industry. IoT enables devices and machines to communicate with each other and share real-time data, improving decision-making and troubleshooting.

In the future, PCF fixtures will be equipped with IoT sensors that monitor the status of the fixture and the part being held. These sensors can detect issues such as misalignment, wear and tear, or improper clamping. If a problem is detected, the system can alert operators to make adjustments, preventing costly errors and downtime.

5. AI and Machine Learning in PCF FixturesArtificial intelligence (AI) and machine learning (ML) are poised to revolutionize many aspects of smart manufacturing. By analyzing large volumes of data, AI systems can make predictions, optimize processes, and enhance decision-making.

In the context of PCF fixtures, AI and ML will enable adaptive clamping systems. These systems will learn from past manufacturing data to automatically adjust clamping force, positioning, and alignment based on the part being processed. This level of adaptability will improve the precision and consistency of production, even when dealing with complex or variable parts.

6. Customization and Flexibility: The Future of PCF FixturesManufacturing processes are becoming more diverse, with companies increasingly needing to produce a wide variety of products. To keep up with this demand, manufacturers are turning to flexible production systems that can handle multiple product designs without extensive reconfiguration.

PCF fixtures will be designed with greater customization in mind. The future will see modular and adaptable fixtures that can be easily reconfigured to accommodate different parts and processes. These flexible fixtures will support the manufacturing of various product lines, reducing setup times and increasing production versatility.

7. Reducing Material Waste with Smart PCF FixturesAs sustainability becomes a priority in manufacturing, reducing material waste is a critical goal. Manufacturing processes often generate waste due to misaligned parts, defective products, or inefficient use of raw materials.

PCF fixtures will help reduce waste by ensuring that parts are held securely and precisely, minimizing errors and defects. Additionally, smart fixtures will be able to detect when a part is improperly aligned or when there are issues with the clamping process, allowing for immediate corrective actions. This real-time feedback will reduce scrap rates and improve overall material efficiency.

8. Enhancing Worker Safety with Smart FixturesManufacturing environments can be hazardous, and worker safety is always a top concern. Improperly secured parts or faulty fixtures can lead to accidents, injuries, and downtime.

In the future, PCF fixtures will be equipped with safety features such as sensors that monitor pressure, force, and positioning. If a part is not clamped securely, the system can alert operators to take corrective action. Furthermore, smart fixtures will be integrated with safety protocols that ensure that workers are kept at a safe distance from dangerous machinery.

9. The Integration of PCF Fixtures in Industry 4.0Industry 4.0 refers to the next generation of manufacturing, where factories are more connected, data-driven, and automated. The integration of IoT, AI, robotics, and other technologies is driving this transformation.

PCF fixtures will be a key part of Industry 4.0, seamlessly integrating into smart manufacturing ecosystems. These fixtures will communicate with other machines, sensors, and systems to optimize production processes, ensure precision, and improve overall efficiency. With the continued development of Industry 4.0, the role of PCF fixtures in smart factories will become even more critical.

10. The Future Outlook for PCF Fixtures in Smart ManufacturingThe future of PCF fixtures in smart manufacturing is bright, with innovations in automation, AI, and IoT pushing the boundaries of what’s possible. As manufacturers continue to seek ways to improve efficiency, reduce costs, and enhance precision, PCF fixtures will play a central role in achieving these goals.

By embracing these advanced fixtures, manufacturers can future-proof their operations, improve product quality, and stay competitive in an increasingly fast-paced and data-driven industry.

ConclusionAs smart manufacturing continues to evolve, the future of PCF fixtures looks incredibly promising. With advancements in automation, AI, IoT, and adaptability, these fixtures will become even more integral to the production process. By enhancing precision, reducing downtime, improving safety, and enabling real-time monitoring, PCF fixtures will help manufacturers stay ahead of the curve and address the unique challenges of the future.

For businesses looking to maximize efficiency, reduce waste, and improve quality, investing in PCF fixtures will be a crucial step in ensuring success in the age of smart manufacturing.